|

Electrostatic Spark Discharge (ESD) is a lubricant degradation mechanism that has been found to occur in fluid systems when oil passes through small passages such as filters, hydraulic valves and bearings. There are several factors that increase the risk of ESD, including:

- Lower temperature

- Higher Viscosity

- Higher Oil Density

- Higher Oil Conductivity

- Higher Flow Rates

- Higher Reynolds Number

- Higher Entrained Air

- Lower Levels of Insolubles (dirt)

- Lower Levels of Moisture (<100ppm water)

- Smaller Filter Pore Size

- Poor Filter Design

|

|

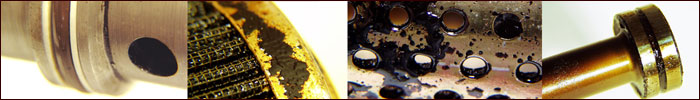

If ESD were occurring, one would expect the chemistry to show thermal cracking (unsaturated hydrocarbon production) and oxidation (ester and acid production). This matches the chemistry identified in the varnish and oil. Further evidence of spark, should be the formation of spark dots that will appear on the metal surfaces of the filters. If this sparking is occurring within the filter, one should observe relatively clean outer surfaces of the filter membranes, and progressively dirty as one progresses inward. Observing the inner core of the canister filters (last-chance filters), these spark dots can be observed, as can be seen in the image above.

|

|

|